High Temperature Fireproof Monolithic Fire Clay Refractory Mortars Price Chamotte Sand High Alumina Castable Powder

Basic Info.

| Shape | Powder |

| Material | Alumina Cement |

| Transport Package | Bag |

| Specification | regular or customized |

| Trademark | KRNC |

| Origin | China |

| HS Code | 3816002000 |

| Production Capacity | 100 Tons/ Day |

Packaging & Delivery

Package Size 77.00cm * 44.00cm * 20.00cm Package Gross Weight 25.000kgProduct Description

High Temperature Fireproof Monolithic Fire Clay Refractory Mortars Price Chamotte Sand High Alumina CASTABLE Powder

Fire clay refractory mortar is of high fire resistance, strong glass erosion resistance, good operational performance, strong bonding property, good water retaining property & workability and without sediment by making it into a slurry. It combines with ceramic under high temperature further improving all properties. High packing density and less water consumption make the compact structure of brickwork.

Using Method:

Please stir the well with water while using it. The volume of water changes according to consistency. The mud hanging should be full and even while construction.

The refractoriness of fire clay refractory mortar is 1580~1750ºC, with a water content of ≤6%. The Fe2O3 content for blast furnace construction should be less than 2.5%.

Contents of Fire Clay Refractory Mortar and Binding Clay

High Alumina Refractory Mortar

The main material of high alumina refractory mortar is high chamotte, the binding agent is soft clay or a chemical bond. The content of Al2O3 is determined by the brick composition and using the request of the construction part. It can be widely used in all kinds of industrial furnaces with high alumina bricks, such as the construction of furnace roof, regenerative chamber, combustion chamber and other parts of the hot-blast furnace, the upper part and other parts of blast furnace, the repair of furnace top, furnace wall and other parts of industrial furnaces.

According to the content of Al2O3, high alumina refractory mortar can be divided into LN-55A, LN-65A and LN-75A, for blast furnace construction should be within 2.5%. The refractoriness is 1750~1790ºC, and loss on ignition should be ≤5%.

Contents of High Alumina Refractory Mortar

- Overview

- FAQs

Refractory fire mortar is the auxiliary product for the construction of refractory brick and furnace walls, mainly including fire clay refractory mortar, high alumina refractory mortar, siliceous refractory mortar, magnesia refractory mortar, etc.

Fire Clay Refractory Mortar

Fire clay refractory mortar is of high fire resistance, strong glass erosion resistance, good operational performance, strong bonding property, good water retaining property & workability and without sediment by making it into a slurry. It combines with ceramic under high temperature further improving all properties. High packing density and less water consumption make the compact structures of brickwork.

Using Method:

Please stir the well with water while using it. The volume of water changes according to consistency. The mud hanging should be full and even while construction.

The refractoriness of fire clay refractory mortar is 1580~1750ºC, with a water content of ≤6%. The Fe2O3 content for blast furnace construction should be less than 2.5%.

Contents of Fire Clay Refractory Mortar and Binding Clay

| Name | For Blast Furnace & Fine Grain | Medium Grain | Coarse Grain |

| Chamotte | 80-85% | 75-80% | 65-75% |

| Binding Clay | 15-20% | 20-25% | 25-35% |

High Alumina Refractory Mortar

The main material of high alumina refractory mortar is high chamotte, the binding agent is soft clay or a chemical bond. The content of Al2O3 is determined by the brick composition and using the request of the construction part. It can be widely used in all kinds of industrial furnaces with high alumina bricks, such as the construction of furnace roof, regenerative chamber, combustion chamber and other parts of the hot-blast furnace, the upper part and other parts of blast furnace, the repair of furnace top, furnace wall and other parts of industrial furnaces.

According to the content of Al2O3, high alumina refractory mortar can be divided into LN-55A, LN-65A and LN-75A, for blast furnace construction should be within 2.5%. The refractoriness is 1750~1790ºC, and loss on ignition should be ≤5%.

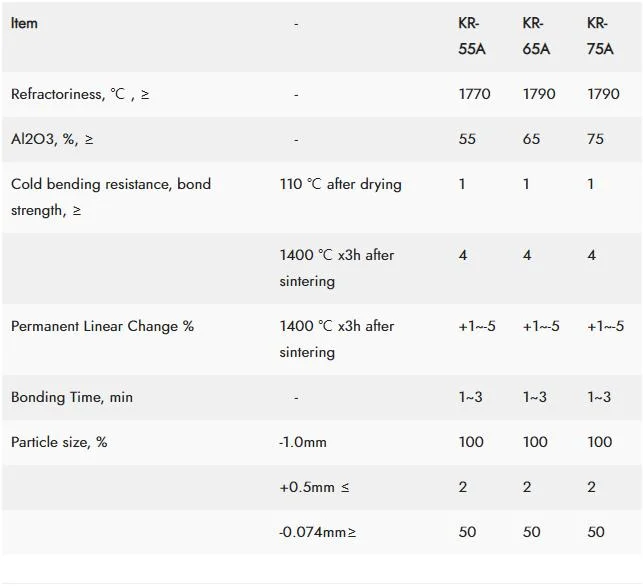

| Item | - | KR-55A | KR-65A | KR-75A |

| Refractoriness, ºC , ≥ | - | 1770 | 1790 | 1790 |

| Al2O3, %, ≥ | - | 55 | 65 | 75 |

| Cold bending resistance, bond strength, ≥ | 110 ºC after drying | 1 | 1 | 1 |

| 1400 ºC x3h after sintering | 4 | 4 | 4 | |

| Permanent Linear Change % | 1400 ºC x3h after sintering | +1~-5 | +1~-5 | +1~-5 |

| Bonding Time, min | - | 1~3 | 1~3 | 1~3 |

| Particle size, % | -1.0mm | 100 | 100 | 100 |

| +0.5mm ≤ | 2 | 2 | 2 | |

| -0.074mm≥ | 50 | 50 | 50 |

Siliceous Refractory Mortar

Siliceous refractory mortar can be divided into three types (93, 90, 85) based on physical & chemical indexes. The refractoriness is 1580~1700ºC.

The grain composition: the grain remnant on a 1.0mm sieve should be within 3%, and the grain past 0.2mm sieve should be more than 80%.

Magnesia Refractory Mortar

Magnesia refractory mortar is divided into MgO-82 and MgO-78 according to physical & chemical index. The content of SiO2 is 5%-9%, and loss on ignition should be ≤2%.

Notes: Because magnesia refractory mortar is of thixotropy, it should be hit until being soft from the bucket before use.

Notes: the kind of refractory brick you use determines the kind of refractory mortar you should choose. If you are not clear, contact us, and we will recommend you a suitable product.