Category

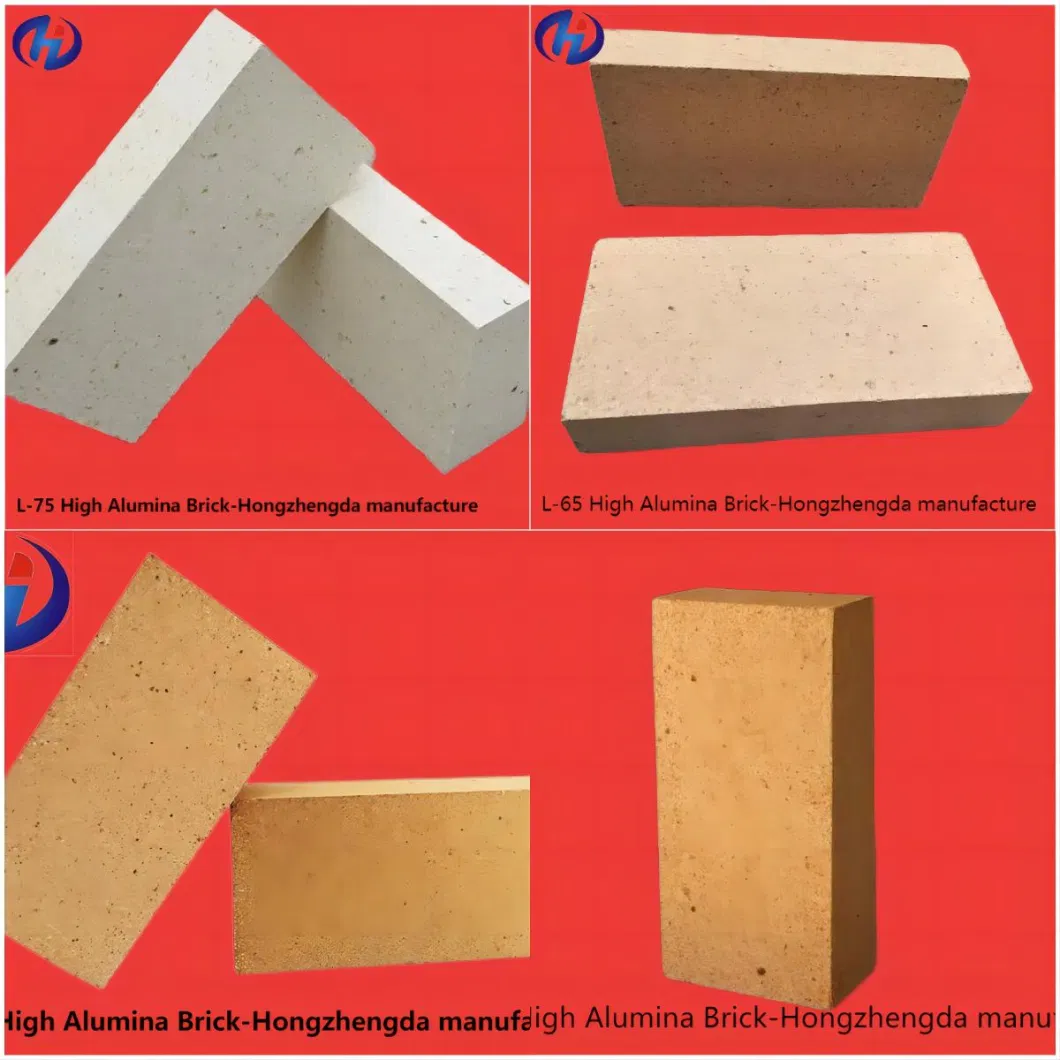

Sk34 Sk36 High Alumina Brick for Glass Kiln Insulation Clay Refractory Brick

Product description High Alumina Brick: High alumina brick production process: high alumina ore (AI2O3 content of higher

Basic Info.

| Model NO. | GB230-114-65 Customized by drawing |

| Normal Temperature Compressive Strength | ≥40-60MPa |

| Bulk Density | ≥2.50(2.45) |

| Load Softening Onset Temperature | ≥1600°c |

| Fire Resistance | ≥1690°c |

| Porosity | ≤25% |

| Al2O3 | ≥ 48-75% |

| Transport Package | Wooden Pallet |

| Specification | 230-115-65 |

| Trademark | Hongzhengda Refractory |

| Origin | Chengdu, Sichuan |

| HS Code | 6902200000 |

| Production Capacity | 50, 000 Tonnes/Year |

Product Description

Product descriptionHigh Alumina Brick:

High alumina brick production process: high alumina ore (AI2O3 content of higher aluminium ore) as the main raw material, high purity alumina powder, etc., auxiliary raw materials, soft kaolin as a binder.

Clinker by grading classified sieve, particle grading, stirring evenly, the formation of mortar-like material, the

Brick Forming: Load the material into the mould, use pressure and vibration to exhaust and press, according to the grade of high alumina bricks, adjust the pressure of the equipment, so that the bricks reach the standard.

Drying: The moulded bricks are put in the drying room for natural drying and preheating drying by kiln, controlling the drying time and temperature to ensure that the moisture inside the bricks is fully evaporated.

Sintering: Push the brick billets from the drying room to the sintering kiln at regular intervals and under high temperature conditions, combine the material particles of the brick billets through high temperature sintering to form a dense crystalline structure, and control the time and temperature of sintering to ensure the mechanical strength and refractory performance of the high alumina bricks.

Cooling and packaging: Timing from the sintering kiln to the cooling section, cooling, control the cold time, after the cold time, push out from the kiln, according to the brick type, according to the customer's requirements for packaging.

| Refractory bricks | |

| Al2O3 | ≥ 55% |

| fire resistance | ≥1690°C |

| Porosity | ≤25% |

| Normal temperature compressive strength | ≥40MPa |

| Rate of change of refiring line | -0.1-+0.3(1500°C×2h)% |

| Load softening onset temperature | ≥1600°C |

| Bulk density | ≥2.50(2.45) |

| Thermal shock stability 1100°C, water-cooled | ≥20% |

Part of the company's project co-operation

Reasons to choose us

Years of industry experience and trustworthy products.

Focusing on R&D and manufacturing of refractory materials.

Quality assured, fast delivery.

Delivery without worry, rest assured procurement.

Manufacturer manufacturing. Processing customised.

Company strength display

Years of industry experience, products are trustworthy.

Q&A

1: Are you a trading company or a manufacturer?

We are a manufacturer. Since our establishment, we have specialised in manufacturing and development. We are located in Chengdu, Sichuan province, with 16000 square metres of production base. With many types of presses, hydraulic presses production equipment, our production speed is 100 tonnes per day. Our products are widely acclaimed both at home and abroad and are in strict compliance with international standards. We have deep co-operation with large domestic companies and the quality of our products is guaranteed. Our products comply with YB/T5106-2009 standard. Our products are mainly used in high temperature industrial kilns, metallurgy, new energy, electric power, steel mills and other industries.

2: Do you accept customised products?

Yes, we provide customised service from product type, specification, parameter, quality requirement, packing and shipping method to meet customers' different needs.

3: What about the goods?

We will choose the suitable mode of transport according to customers' requirements. Usually by sea or railway.

4: What are the payment terms?

30% in advance, pick up and pay, 70% payment.

5: How do you ensure the quality of your products?

Each batch of products will be tested, if customers need, samples can be randomly selected by a third party testing company out of the test certificate to ensure the quality of goods.

6: When can I receive the goods after submitting the order?

Sample order: 1-3 days; Mass production: 30-35 working days