Refractory High Alumina Super Duty Fire Brick for Furnace Lining

Basic Info.

| Model NO. | YUFENGREC-A36, YUFENGREC-A40, YUFENGREC-A42 |

| Size(Shapes) | Straights, Arch, Wedge, Soaps, Splits... |

| Transport Package | Export Standar Wooden Pallet |

| Specification | ASTM Standard |

| Trademark | YUFENGREC |

| Origin | China |

| HS Code | 69022000 |

| Production Capacity | 30000 Tons /Year |

Product Description

YUFENGREC® Fireclay Brick & High Alumina Brick are made of high-grade Flint Clay,Chamotte ,High Alumina Bauxite with alumina content from 36% to 85% , producing by drying pressing and high fired .

YUFENGREC® Mullite Bricks based on synthetic fused Mullite and sintered Mullite shaped by high pressure presses or casting process as per different applications and fired in high temperature furnaces . Mullite Brick features with good thermal properties and adequate erosion and corrosion resistance ,which is widely used to hot end of regenerative chambers of glass melter , superstructure of the furnace .

YUFENGREC® Andalusite Bricks is made by non-contaminated andalusite from natural sources as the raw material ,shaped by hydraulic high pressure presses .During the production processing, the bricks is strictly controlled with the reasonable particle size of the raw materials ,adopt new process , multi-stage ingredients, matrix homogenization, and determines the best calcination temperature etc., to achieve high quality level to meet the use of different parts of blast furnace and hot blast stove and different working environments

Classification : ASTM C-27

Method of Manufacturer: Dry Pressing

Key Features

* High Strength

* Lower Shrinkage

* Excellent Alkalis Resistant * Good resistant to Thermal Shock* High Refractoriness under loadTypical Applications

* Carbon Baking pit furnace flue-walls and head walls

* Air Heaters

* Combustion Chamber .

* Boiler

* Stack

* Blast Furnace

* Hot Blast Stove

* Cement Rotary Kiln

* Glass Furnace

* kinds of high temperature industry furnace

Dimensions

* 230 x 114 x 64 mm * 230 x 114 x 76 mm* 250 x 124 x 64 mm* 220 x 110 x 60 mm* Customized production for bricks with special dimension is available

Packing

* In export standard wooden pallet

Typical Technical Data

* Fireclay Brick

| Item | Fireclay Brick | ||

| High Duty Fireclay Brick | Super Duty Fireclay Brick | High Fired ,Super Duty, Dry Press Fireclay Brick | |

| Al2O3 | ≥36 % | ≥42 % | ≥42.1 |

| Fe2O3 | ≤2.5% | ≤2.5% | ≤2.0 |

| Pyrometric Cone Equivalent Orton Standard Cones Temperature Equivalent | 32 1717ºC | 34 1753ºC | 34 1753ºC |

| Bulk Density | ≥2.15 | ≥2.20 | ≥2.29 |

| Apparent Porosity | 22-24% | 22-24% | 17-19% |

| Cold crushing strength | ≥25 | ≥35 | ≥42 |

| Hot Load Test Deformation at 1350ºC | 1% | -0.2 to -0.7% | ≥05-0.7% |

| Permanent Linear Change at 1400 ºC | -0% | -0% | 0% |

* High Alumina Brick

| Item | High Alumina Brick | |||

| SK36 | SK37 | SK38 | SK40 | |

| Al2O3 | 55% | 60 | 70 | 79.6 |

| Fe2O3 | 2.0% | 2.0% | 2.0% | 2.0% |

| Pyrometric Cone Equivalent Orton Standard Cones | 35 | 37 | 38 | 40 |

Bulk Density | 2.30 g/cm3 | 2.35g/cm3 | 2.45 g/cm3 | 2.60 g/cm3 |

Cold crushing strength | 31 MPA | 44 MPA | 48 MPA | 55 MPA |

Apparent Porosity | 22% | 22% | 21% | 20% |

Permanent Linear Change at 1600 ºC | +0.1 to +2.5% | +1.5 to +2.5% | +2.0 to +4.0% | +1.0 to +2.0% |

* Special High Quality Fireclay Brick with Low Porosity

| Item | Unit | Special High Quality FireClay Brick With Low Porosity | ||

| YUFENG-DN11 | YUFENG-DN14 | YUFENG-DN17 | ||

| Al2O3 | % | ≥47 | ≥45 | ≥42 |

| Fe2O3 | % | ≤1.20 | ≤1.5 | ≤1.80 |

| Bulk Density | g/cm3 | ≥2.40 | ≥2.34 | ≥2.26 |

| Apparent Porosity | % | ≤11 | ≤14 | ≤17 |

| Cold crushing strength | MPa | ≥80 | ≥65 | ≥50 |

| Permanent Linear Change at 1400 ºCx 2h | % | - | +0.1 to -0.2% | +0.1 to -0.2% |

| at 1500 ºCx 2h | +0.1 to -0.2% | - | - | |

| Refractoriness Under Load 0.2 MPa T0.5 | T0.5 /ºC | ≥1520 | ≥1470 | ≥1430 |

* Andalusite Brick

| Item | Unit | Andalusite Brick | ||

| YUFENGREC-A-55 | YUFENGREC-A-60 | |||

| Al2O3 | % | ≥55 | ≥60 | |

| Fe2O3 | % | ≤1.0% | ≤1.5% | |

| Bulk Density | g/cm3 | ≥2.45 | ≥2.50 | |

| Apparent Porosity | % | 22 | 22 | |

| Cold crushing strength | MPa | ≥40 | ≥45 | |

| Permanent Linear Change | 1500 ºCx 3h | % | +/- 0.2 | +/- 0.2 |

| Refractoriness Under Load (2kg/cm2,T2) | ºC | 1450 | 1500 | |

* Mullite Brick

| Item | Unit | Casting Corundum-Mullite | Sintered Mullite | Fused Mullite | Sintered Corundum -Mullite | Casting Mullite | |||||

| CCM85 | CCM80 | SM65 | SM70 | SM75 | SM80 | FM75 | SCM85 | SCM80 | M70 | ||

| Al2O3 | % | 85 | 80 | 64 | 68 | 74 | 78 | 72 | 85 | 80 | 69 |

| Fe2O3 | % | 0.5 | 0.5 | 1.2 | 1.2 | 0.8 | 0.6 | 0.5 | 0.5 | 0.5 | 0.8 |

| Refractoriness | ºC | 1810 | 1810 | 1790 | 1790 | 1790 | 1810 | 1810 | 1810 | 1810 | 1790 |

| Bulk Density | g/cm3 | 21 | 22 | 18 | 20 | 18 | 18 | 18 | 18 | 18 | 20 |

| Apparent Porosity | % | 2.75 | 2.65 | 2.45 | 2.50 | 2.60 | 2.75 | 2.65 | 2.90 | 2.80 | 2.50 |

| Cold Crushing Strength | MPa | 60 | 60 | 55 | 60 | 65 | 70 | 70 | 80 | 70 | 60 |

| Refractoriness Under Load | ºC | 1700 | 1650 | 1560 | 1580 | 1650 | 1700 | 1700 | 1700 | 1700 | 1650 |

| Permanet Linear Change 1400 ºC x 2h | % | --- | --- | --- | --- | --- | --- | --- | --- | --- | --- |

| 1500ºC x 2 h | + 0.1 - 0.2 | + 0.1 - 0.2 | + 0.1 - 0.4 | + 0.1 - 0.3 | + 0.1 - 0.2 | + 0.1 - 0.2 | + 0.1 - 0.1 | + 0.1 - 0.1 | + 0.1 - 0.1 | + 0.1 - 0.2 | |

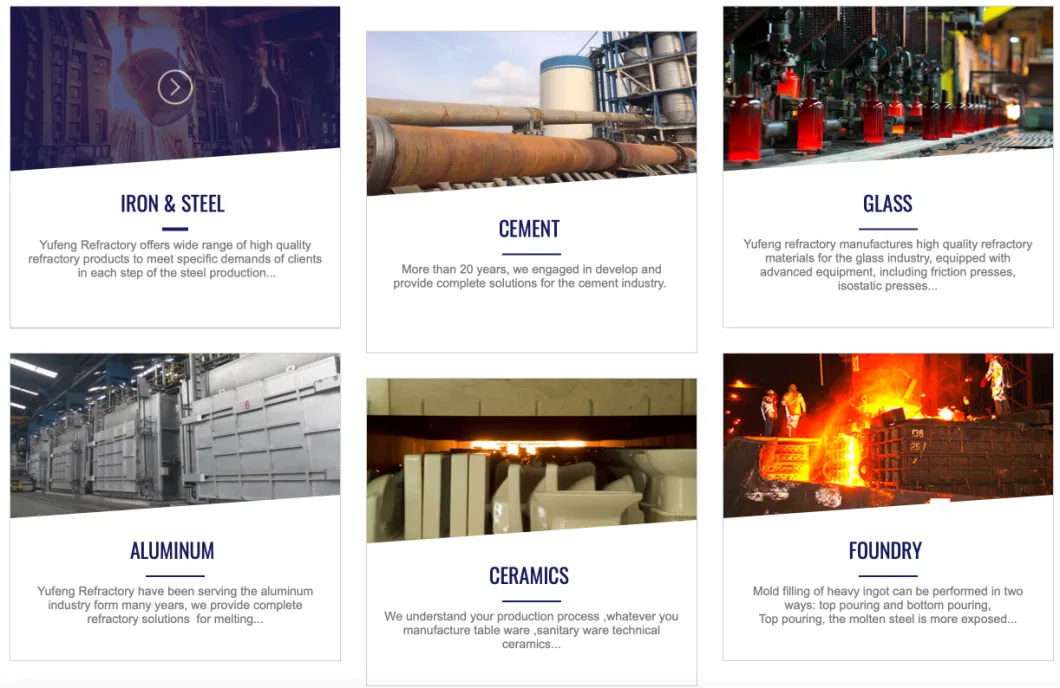

Producing Procedure QC Inspection

Applications ZIBO YUFENG REFRACTORY CO,LIMITED products are widely usedand can be applied to multiple scenes.